Elérhetőségeink

Cím: 8300 Tapolca, Kossuth u. 2.

Telefon/Fax: 87/413-569

Email: titkarsag@elmolight.hu

Telephely nyitvatartása: hétfőtől-péntekig 7-15 óráig

Treatment and utilisation of mycelium sludge residing after fermentation procedure in pharmaceutical factory

As the result of our research work, we have developed starter cultures, by the application of which – providing the technology-controlled living conditions – it is possible to compost biomasses of different origin in a fast and efficient way, soil polluting hazardous waste can be efficiently broken down: hydrocarbon derivatives, animal and vegetable fats, oils and pharmaceutical organic hazardous waste, too.

Our current team of experts has worked out already in the 1980’s, together with Biogal Pharmaceutical Company the technology, in which the mycelia slurries remaining as hazardous waste after the production of antibiotics carried out there by fermentation processes, have become utilisable as the raw material for producing certain products.

After the that-time production of penicillin, oxy-tetracycline, bacitracin, gentamicin, etc., following the injection of the slurries – yet containing remains of active ingredients – by an aerobic inoculum (mixed culture), the active ingredients have become broken down, thus by a further treatment of the remaining organic slurries, we have got products which can be utilized as a compost.

In the course of the last year we have worked out discharging procedures also for slurries with lovastatin, tobramycin, deferoxamine, mycophenolic acid, vancomycin, lysergic acid, etc., for example, we are able to break down mycophenolic acid in only 40 days. We inoculate the – already harmless – fungal mycelium-, filter media and media residue complex, remaining after the breakdown of active ingredients, by various – selected, identified and state-controlled, GMO-free - mixed cultures on an industrial scale, and we create compost in an aerobic way with a cycle time of 60 days, or an even more valuable hummus manure in an anaerobic way, with a cycle time of 40 days (e.g. Cofuna).

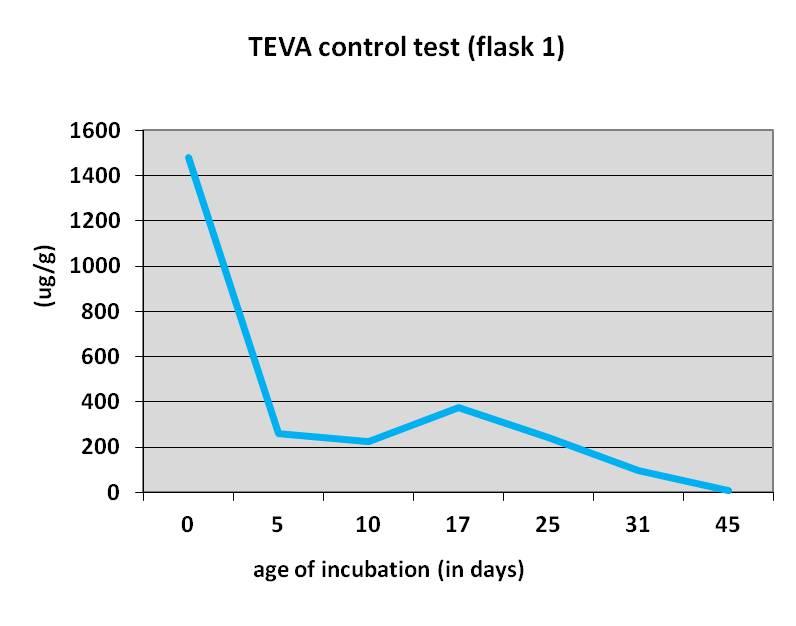

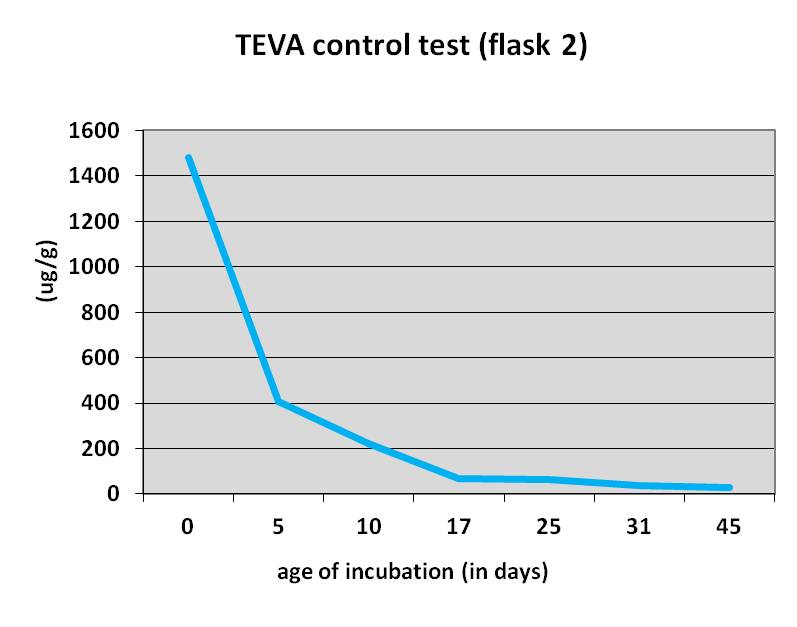

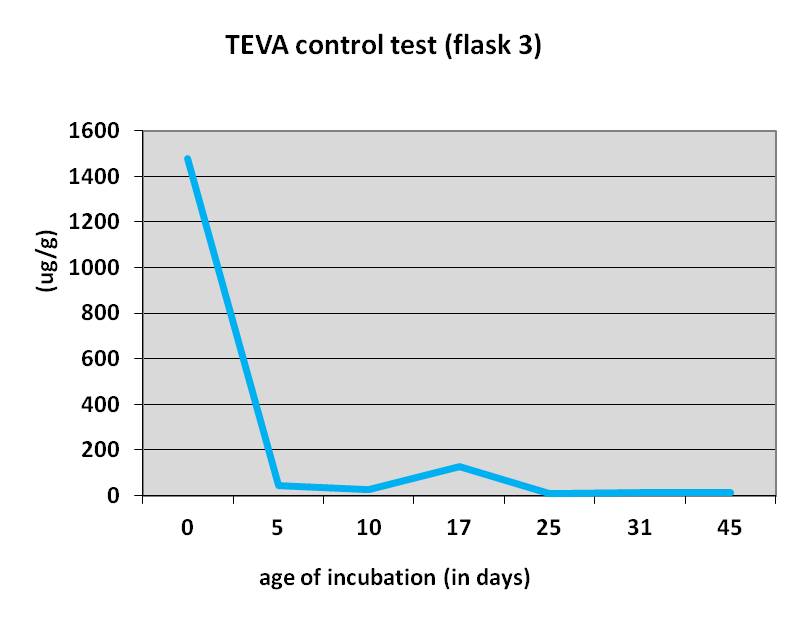

During the past years our technology has attracted the attention of TEVA Pharmaceuticals, too. Apart from the above – within the framework of a confidentiality contract – we have handed over our strains used for the breakdown of active ingredients remaining in the waste after the pharmaceutical manufacturing process to TEVA, for the examination of their products. (It carries out tests with the new active ingredients only in internal tests, we did not have the opportunity to receive the waste for the purpose of preliminary breakdown tests, compared to cases with the waste of the previously listed produces).

According to the report of the laboratory of TEVA, the residue of the new active ingredient had been broken down by the handed-over mixed culture in 30-40 days.

TEVA control test for an experimental product of TEVA, with the vaccine of Elmolight Biomass Pharma

In other words, we prepare from the wastes (raw material) previously belonging to the category of hazardous waste a compost with a high active ingredient content – having an unrestricted trade-marketing authorization. These can be utilized and are well-sellable products in the agricultural field.

Four products have already been the subject of all control tests of special authorities (plant Protection nand Soil Conservation Service, National institute of Public Health), and our below four compost products have been accepted for authorization by the Agricultural Office, which, after the tests has issued the unrestricted trade-marketing authorisation:

- Biomass Super Extra compost

(Tobramicin)

- Biomass Super Komplex compost

(Mycophenolic acid)

- Cofuna-Biopost hummus manure

(Mixed mycelium slurry: consisting of a mixture of tobramycin, deferoxamine, mycophenolic acid and vancomycin)

- Biomass Super Agriform compost

(slurry of Ewonik-Agroferm Ltd. originating from the production of L-threonine)

By using our technology, the waste of fermentation processes can be treated on an industrial scale.